Description

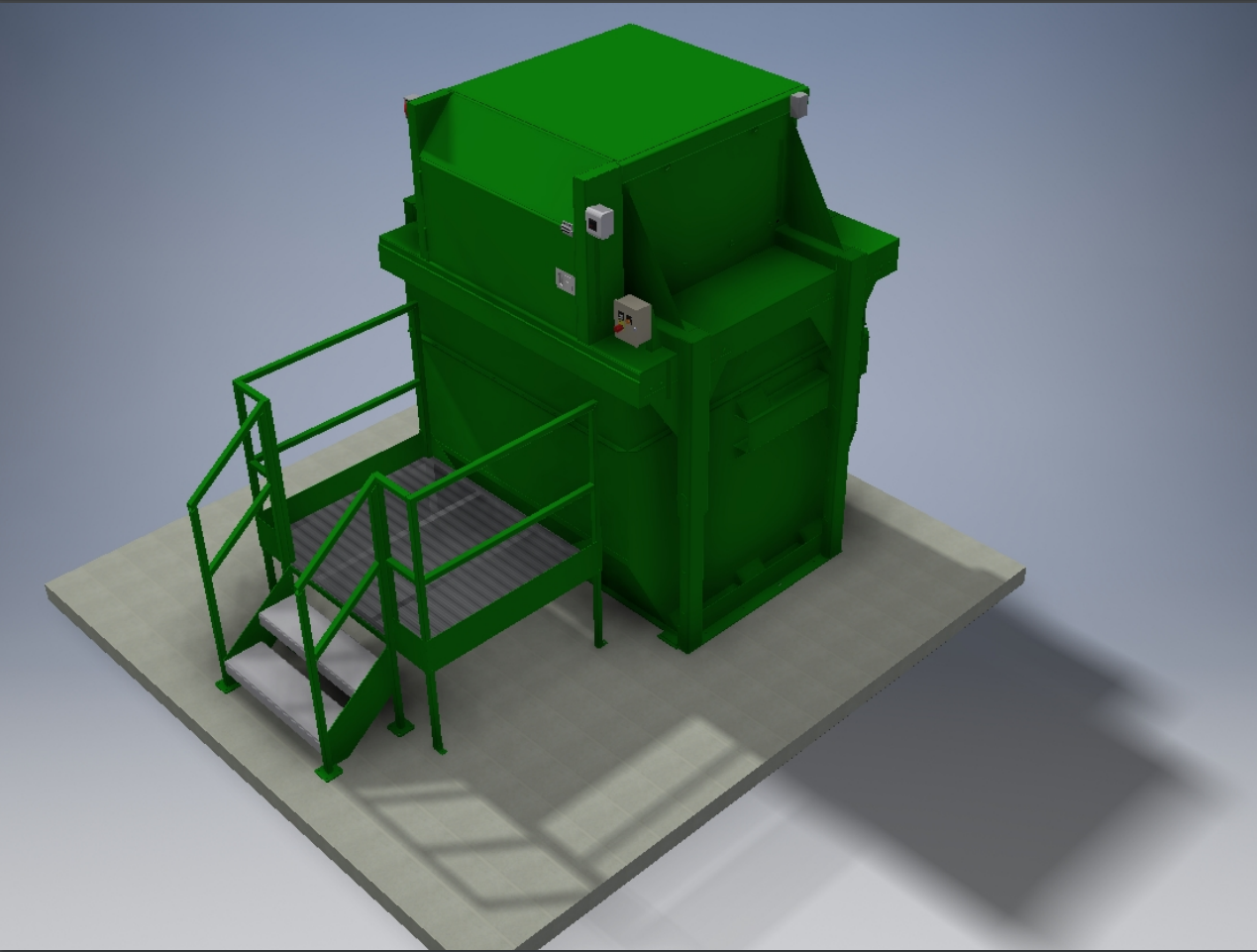

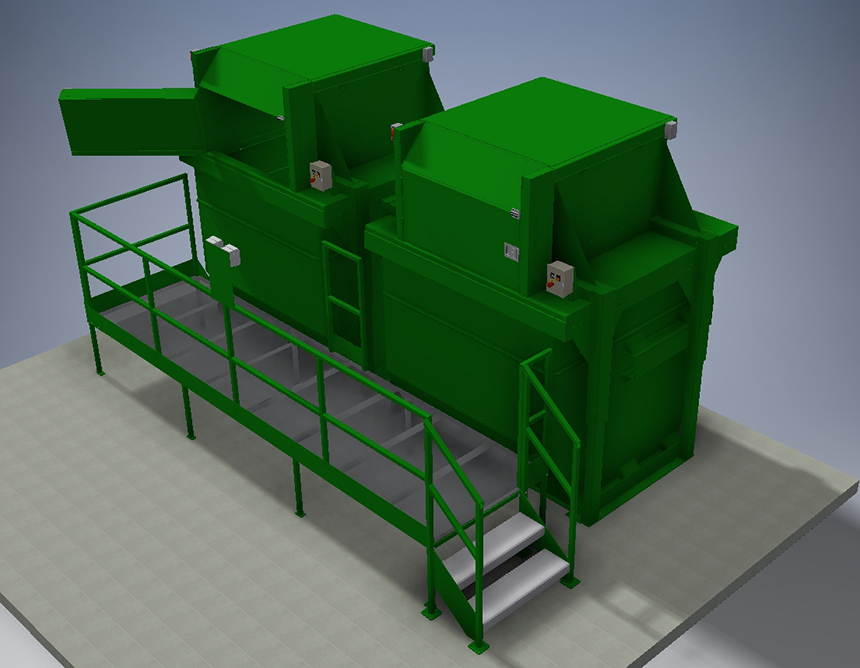

The TV-2000 is a “front-end” based self-contained compactor that is specifically designed for waste streams that contain a large percentage of wet waste. The self-contained compactor will contain all of the waste stream liquids in the front-end style container that is positioned directly under the compactor head. Unlike our other roll-off based “SPH” models, this unit is designed to be dumped by standard front-end style waste trucks. Each compactor is manufactured with a container that has fully welded seams, contains a full liquid sump area and is equipped with side pockets to accommodate the forks of a front-end waste truck. This model is available in a wide range of configurations (front load, side load and rear load), is available with 4, 6 or 8 cubic yard containers; and can be customized to fit our clients individual needs.

Technical Details

Standard Features

- UL/CSA Approved Design

- Meets/exceeds ANSI Z245.2 regulations

- Meets/exceeds OSHA regulations

- PLC “flex-design” based control systems

- NEMA 4 rated enclosure

- Internal timers prevent system run-on

- Self-diagnostic indicators

- 24-volt controls

- Adjustable multi-cycle timer

- 75% and 100% full light

- Auto-alert maintenance mode

- Heavy duty oil-tight pushbutton controls

- Key lockable start pushbutton

Mechanical Specifications

| TV2000-4 | TV2000-5 | TV2000-6 | TV2000-8 | |

|---|---|---|---|---|

| Charge chamber volume | 1 cu. yd. | 1 cu. yd. | 1 cu. yd. | 1 cu. yd. |

| Charge chamber opening size | 33″ x 48″ | 33″ x 48″ | 33″ x 48″ | 33″ x 48″ |

| Ram face size | 48″ x 34″ | 48″ x 34″ | 48″ x 34″ | 48″ x 34″ |

| Ram penetration | 29.5″ | 29.5″ | 29.5″ | 29.5″ |

| Compaction force normal | 28,260 lbs | 28,260 lbs | 28,260 lbs | 28,260 lbs |

| Compaction force maximum | 33,912 lbs | 33,912 lbs | 33,912 lbs | 33,912 lbs |

| Cycle time | 34 seconds | 34 seconds | 34 seconds | 34 seconds |

| System pressure normal | 2000 psi | 2000 psi | 2000 psi | 2000 psi |

| System pressure maximum | 2400 psi | 2400 psi | 2400 psi | 2400 psi |

| Pump capacity | 3 gpm | 3 gpm | 3 gpm | 3 gpm |

| Motor size | 1 hp/3 hp | 1 hp/3 hp | 1 hp/3 hp | 1 hp/3 hp |

| Cylinder size | 2 x 3″ | 2 x 3″ | 2 x 3″ | 2 x 3″ |

| Cylinder type | Double acting | Double acting | Double acting | Double acting |

| Ram face pressure normal | 17.4 psi | 17.4 psi | 17.4 psi | 17.4 psi |

| Ram face pressure maximum | 20.8 psi | 20.8 psi | 20.8 psi | 20.8 psi |

| Oil tank capacity | 8 gal | 8 gal | 8 gal | 8 gal |

| Shipping weight (Head only) | 1485 lbs | 1485 lbs | 1485 lbs | 1485 lbs |

Electrical Specifications

| Control System | 110 volt 60 cycle powered by step-down transformer |

| Control Panel | Fully wired. Keyed start button, emergency stop, full lights, reset button, PLC, current sensor |

| Power | 208/575 volt, 3 phase/220 volt, single phase |

Dimensions

| Container | A | B | C | D |

|---|---|---|---|---|

| 4 yd | 45″ | 85″ | 93″ | 84″ |

| 5 yd | 48″ | 89″ | 93″ | 84″ |

| 6 yd | 56″ | 101″ | 93″ | 84″ |

| 8 yd | 79″ | 119″ | 93″ | 84″ |

Optional Equipment

- Advance – warning light

- Fluid – filled pressure gauge

- Oil heater

- Odour control system

Electrical system upgrades

- System monitor: SCADA panel (add-on panel or integrated upgrade) provides cell-based monitoring of all systems including container fullness, safety circuit devices, container positioning, hydraulic system devices including reservoir fullness, oil temperature and system in-use time

- Remote start/stop station

- Auto-start system (photo-eye or sonic sensor)

- Wireless remote control

- Biometric interface

- HMI based operator interface for tie into building monitoring systems

Hydraulic system upgrades

- Single phase and three phase power units

- Hi-lo hydraulic pumps for reduced cycle time applications

- Regen circuit for improved hydraulic fluid circulation

- Over-sized oil reservoirs to accommodate ancillary devices and improved heat sink

- Oil cooler for high duty cycle applications

- Bio-degradable oil

- In tank oil heater

- Sonic sensors for oil fullness monitoring

- Low temperature oil (as low as -60 Celsius is available)

Compactor upgrades

- Custom chute systems

- Custom weather enclosures

- Drive-on deck systems (certified up to 20,000 lbs.)

- Tongue and grooved floor designs

- AR plate floors and sides for reduced press head/compactor shell wear

- Pad-less set-up for installation on asphalt

- Custom hydraulic cart tipping systems

- Light curtain-based safety sensors

- Custom steel safety barriers

- Custom hydraulic lift systems